|

Articles

on Mass Flow

Flow Research is

proposing a first-ever Mass

Flowmeter Series with a Core Overview Study, The World Market for Mass Flow

Measurement and

in-depth studies on three types of flowmeters that measure mass flow

directly:

·

The

World Market for Coriolis Flowmeters, 7th Edition

·

The

World Market for Thermal Flowmeters, 3rd Edition

·

The

World Market for Mass Flow Controllers, 4th Edition.

Each of these separate

studies in the series is interesting in its own right, but the Core Study

is composed of high-level results from each of the studies to give a

comprehensive picture of the entire mass flowmeter market. We also include

data on multivariable mass flowmeters in this Core Study.

Core Study Goals

This

executive-level study will determine the size of the entire mass flowmeter

market in 2022 and forecast market growth through 2027. Segmentation will

include total worldwide market size broken down by eight geographic

regions and the basic mass flow technology types: Coriolis, thermal, MFC

and multivariable flowmeters.

The study has multiple objectives:

·

Show worldwide market size and shares for the mass flow market in

2022 for Coriolis, thermal, mass flow controllers (MFCs), and

multivariable flowmeters

·

Forecast mass flowmeter market growth through 2027

·

Share top-level data about each of the types

·

Segment data both on a worldwide basis and for each of eight

worldwide regions

·

Discuss market forces and suggest strategies

for selling into the mass flowmeter market

About Mass

Flow

While the majority of flowmeters

measure volumetric flow, three types of flowmeters measure mass flow

directly. These three types are Coriolis, thermal, and multivariable

flowmeters. This atudy discusses the reasons for measuring mass flow,

and then looks at the advantages and disadvantages of Coriolis, thermal,

and multivariable flowmeters. Another type, mass flow

controllers, both measure and control the flow. Mass flow

controllers are used both in the semiconductor industry and in industrial

markets.

To

learn more about multi-tech, go to:

Coriolis flowmeters

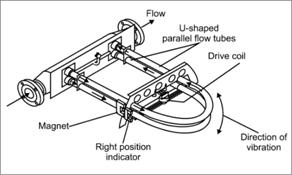

Coriolis

flowmeters use fluid momentum to measure mass flow directly. The

fluid enters the meter and passes through one or more vibrating tubes and

accelerates as it reaches the point of maximum vibration. As

the fluid leaves this point, it decelerates. This causes an

oscillating motion in the tubes. The Coriolis meter measures

this oscillating motion, and mass flow is directly proportional to the

amount of oscillation.

Coriolis

flowmeters are the most accurate meters. Their main limitations are

line size and cost. Over 67 percent of Coriolis flowmeters are

used on line sizes of two inches and less. Coriolis meters become

very large and unwieldy, especially in sizes above four inches. Cost

also increases with size. Even smaller size meters are

generally more expensive than other comparable new-technology flowmeters. Users

who are considering Coriolis flowmeters need to balance their need for

accuracy and reliability against purchase price. Some users select

Coriolis meters despite their higher initial cost, because low maintenance

requirements reduce their cost over the life of the meter. Coriolis

flowmeters are the most accurate meters. Their main limitations are

line size and cost. Over 67 percent of Coriolis flowmeters are

used on line sizes of two inches and less. Coriolis meters become

very large and unwieldy, especially in sizes above four inches. Cost

also increases with size. Even smaller size meters are

generally more expensive than other comparable new-technology flowmeters. Users

who are considering Coriolis flowmeters need to balance their need for

accuracy and reliability against purchase price. Some users select

Coriolis meters despite their higher initial cost, because low maintenance

requirements reduce their cost over the life of the meter.

The

high accuracy of Coriolis meters – up to 0.05 percent – is one of the

major reasons for their continued growth. Companies that need flowmeters

for custody transfer, or want highly accurate measurements in terms of

mass, have good reasons to select Coriolis flowmeters. They find that

despite a relatively high price tag, Coriolis flowmeters can provide a

good return on investment.

Thermal

flowmeters

Thermal

flowmeters are among a small group of fluid measurement technologies that

can generate a mass flow measurement independent of additional component

technologies. Mass flow data

is generally considered more

useful

than volumetric data for many applications - such as custody transfer of

hydrocarbon fluids - and can offer higher repeatability, a level of

measurement certainty highly valued by process and quality control

managers alike. useful

than volumetric data for many applications - such as custody transfer of

hydrocarbon fluids - and can offer higher repeatability, a level of

measurement certainty highly valued by process and quality control

managers alike.

Thermal

flowmeters measure mass flow quite differently from Coriolis flowmeters.

For example, instead of using fluid momentum as Coriolis flowmeters do,

thermal flowmeters make use of the thermal or heat conducting properties

of fluids to determine mass flow. While

most thermal flowmeters are used to measure gas flow, some also measure

liquid flow.

In contrast,

other flowmeter types that can also produce a mass flow result do so with

the addition of pressure and temperature sensors.

Mass flow is then computed from the volumetric flow, and the

temperature and pressure variables. Multivariable

differential pressure and vortex flowmeters can both be used in this way

to compute mass flow.

Mass

Flow Controllers (MFCs)

Mass flow measurement, which measures the mass of a fluid

independent of pressure or temperature, is more reliable and offers a

higher accuracy and repeatability than volumetric flow, which measures the

volume of a gas or liquid occupying a pipe. This difference is

particularly important for gases, which shrink or expand in volume with

changes in pressure or temperature, but whose mass – the number of

molecules – stays constant. Mass flow measurement, which measures the mass of a fluid

independent of pressure or temperature, is more reliable and offers a

higher accuracy and repeatability than volumetric flow, which measures the

volume of a gas or liquid occupying a pipe. This difference is

particularly important for gases, which shrink or expand in volume with

changes in pressure or temperature, but whose mass – the number of

molecules – stays constant.

Fortunately,

a mass flowmeter can easily provide flows in volume by adding the volume

(including the pipe diameter) to the calculation. Conversely, some

volumetric flowmeters e.g., multivariable vortex and differential pressure

flowmeters – can indirectly provide mass flow by also measuring

temperature and pressure and computing the mass flow.

MFC

technology types are thermal, pressure, Coriolis, and ultrasonic.

Because MFCs are used both to measure and to control fluid flows,

the study will identify their use by fluid type.

We will also quantify the presence of MFCs in significant

industries and applications, including semiconductor and industrial.

What are the Advantages of Multivariable

Flowmeters?

Multivariable

flowmeters measure mass flow by combining volumetric flow measurement with

density measurement. Density is usually measured either by consulting

a table, or by dynamically measuring pressure and temperature. This

is called an inferred method, because a formula is used to compute mass

flow. The main types of multivariable flowmeters are

differential pressure (DP), vortex, and ultrasonic.

One main advantage of multivariable

DP flowmeters is that only one process penetration is required to get

three process readings: flow, temperature, and pressure. This reduces

the chance of fugitive emissions, and also the number of leak points. Another

advantage of multivariable DP meters is that users who are already

measuring volumetric flow with a DP flowmeter can upgrade to a

multivariable DP meter with a minimum of changes.

One disadvantage of multivariable

flowmeters is that accuracy levels are not as high as accuracy levels of

Coriolis meters. This is due to the number of variables

involved, and to the fact that it is an inferred method of computing mass

flow. On the other hand, the purchase price of multivariable

flowmeters is substantially below that of most Coriolis meters.

|